Fiberglass flat bar

Fiberglass flat bar is a reinforced composite material made of continuous fiberglass yarns and resin, formed through a thermal pultrusion process.

Fiberglass flat bar is a reinforced composite material made of continuous fiberglass yarns and resin, formed through a thermal pultrusion process. It retains the high-strength characteristics of fiberglass, while the resin coating provides excellent elasticity, corrosion resistance, and durability, making it resistant to cracking or breaking.

Fiberglass flat bars are lightweight yet strong, with a density of only 2/3 that of aluminum and 1/4 – 1/5 that of carbon steel, making them an ideal replacement for metal flat bars in various applications.

With its lightweight, high strength, corrosion resistance, and excellent insulation, fiberglass flat bar has been widely adopted in home decor, construction, transportation, electrical engineering, chemical processing, agriculture, and industrial manufacturing.

Product Features

- Lightweight and high strength(300MPa~600MPa)

- Excellent insulation and flame resistance, suitable for electrical applications

- Corrosion-resistant, weather-resistant, and long lifespan, ideal for outdoor and industrial environments

- Smooth surface and stable dimensions, ensuring precise installation

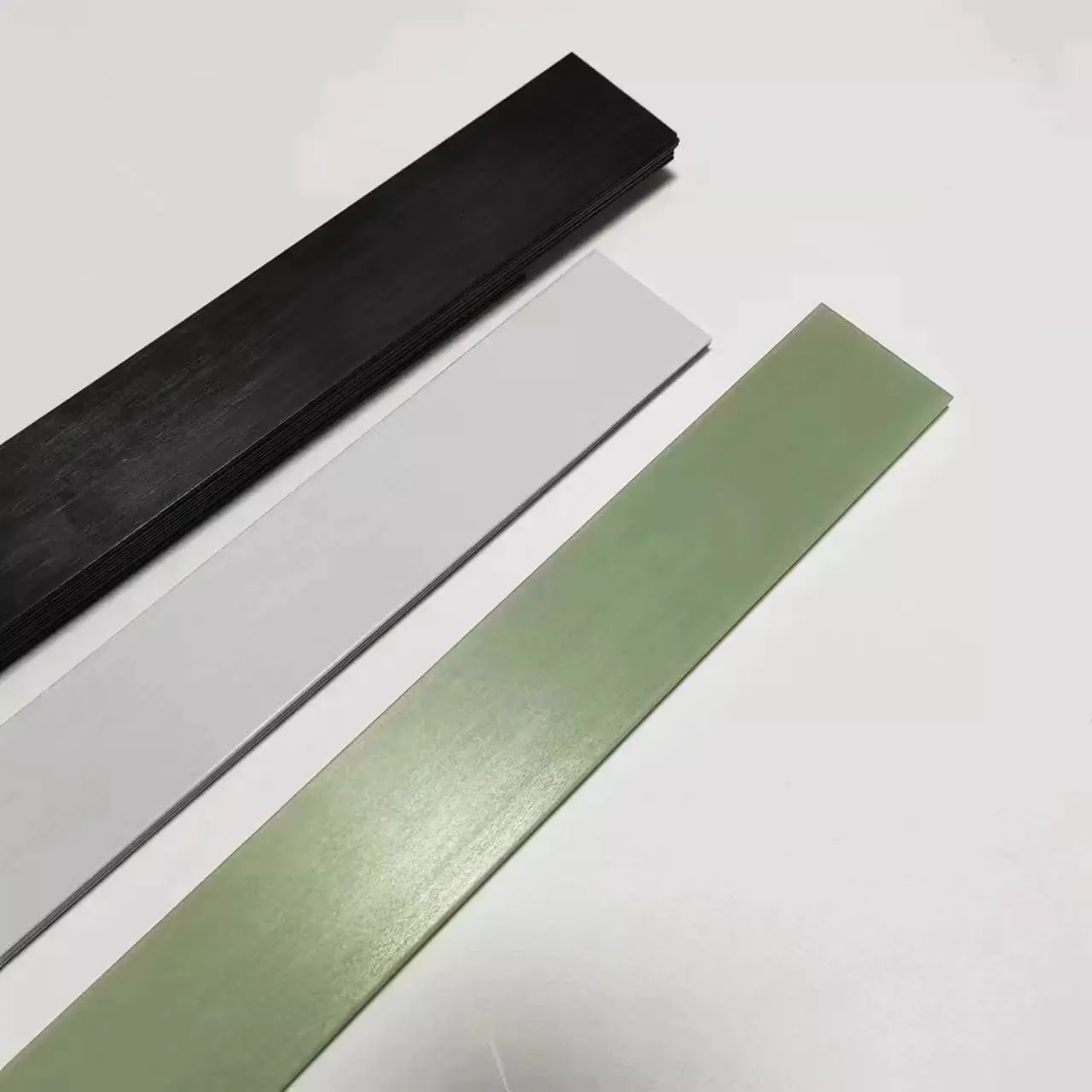

- Available in multiple colors, aesthetically pleasing, and easy to maintain

- Easily machinable(cutting, drilling, turning, polishing, tapping, etc.), making construction convenient

Application of Fiberglass flat bar

Home Decoration and Interior Design

- Window and door frames: Corrosion-resistant and rust-free, suitable for humid environments, replacing traditional metal materials.

- Railings and stair handrails: Lightweight, strong, and aesthetically pleasing, ideal for balconies and courtyard fences.

- Outdoor sunshades: Used for garden pergolas, patio covers, and terrace shading, offering UV resistance and long service life.

Construction and Infrastructure

- Bridge engineering: Used in pedestrian bridges and boardwalks, especially in humid or coastal areas.

- Fences and guardrails: Suitable for highways, factories, and parks, offering durability and low maintenance.

- Roofing and structural elements: Applied in roof support beams and building frameworks to reduce structural weight and enhance safety.

Transportation

- Aerospace: Used in lightweight, high-strength structural components, such as interior aircraft supports.

Electrical and Telecommunications

- Cable trays and insulation rods: Excellent insulation properties for substations and electrical safety protection.

- Signal towers and antenna supports: Used in communication base stations, offering weather resistance and reducing maintenance costs.

Chemical and Environmental Engineering

- Chemical plant equipment supports: Resistant to strong acids and alkalis, ideal for supporting corrosive fluid pipelines.

- Wastewater treatment facilities: Used in drainage covers and filtration grates, ensuring long-term corrosion resistance.

Sports and Recreational Facilities

- Stadium seating structures: Lightweight, durable, and easy to maintain.

- Outdoor facilities: Applied in park pathways, boardwalks, and playground structures, resistant to UV exposure and aging.

Agriculture and Livestock Farming

- Greenhouse frames: Corrosion-resistant and moisture-proof, ideal for long-term exposure to humid environments.

- Poultry farming equipment: Used in cages and partitions, resistant to acids and alkalis from animal waste.

Mechanical and Industrial Applications

- Industrial equipment frames: Used in lightweight machinery supports, reducing structural weight while maintaining strength.

- Conveyor belt structures: Applied in logistics conveyor systems, wear-resistant and low-maintenance.